Introduction

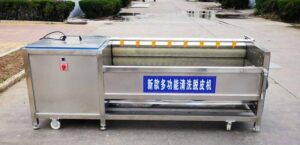

1. Application: The brush roller peeling machine is mainly used for round and oval root vegetable and fruit washing and peeling, like potato, cassava, carrot, lotus root, orange, etc.

2. Principle: It adopts the brush friction principle and high-pressure spray to remove the sludge and the vegetable and fruit skin.

3. Main Composition:

A.Motor:Drive the roller to rotate

B.Nylon roller or Emery roller (Depends on what product you peel)

C.Spray nozzle

4. Feature:

A.Peeling rate up to 95%

B.SUS304 is Waterproof and beautiful

C.High-pressure water spraying, saving water resources

Detailed Information Of Peeler

The body is made of SUS 304 Screw shaft and can unload automatically (For Automatic type)

High-pressure spray nozzle Emery roller for products with hard skin Nylon roller for regular product

Two Types For Choice

Manual discharge type Automatic discharge type

It has a large capacity and discharges by hand It is usually used in the automatic production lines with automatic discharge

Parameters Of Semi-automatic Type

|

Model |

Length of roller |

Dimension |

Power |

Capacity |

|

BTSWP-800 |

800mm |

1200*900*1200mm |

1kw |

300kg |

|

BTSWP-1000 |

1000mm |

1400*900*1200mm |

1.1kw |

500kg |

|

BTSWP-1200 |

1200mm |

1600*900*1200mm |

1.5kw |

800kg |

|

BTSWP-1500 |

1500mm |

1900*900*1200mm |

2.2kw |

1000kg |

Parameters Of Full-automatic Type

|

Model |

Capacity |

Dimension |

Power |

|

BTFWP-2800 |

1000kg/h |

3400*900*1600 |

2.2kw |

Application display