Introduction

The automatic potato chips production line is designed for a large-scale potato chips plant. The capacity can be 100kg/h, 200kg/h,300kg/h,400kg/h, and 500kg/h. We can supply a one-stop service including Factory layout, factory design, equipment installation, debugging, after-sales service, and production process guidance.

Features :

1. High degree of automation

2. Labor-saving

3. Low energy consumption

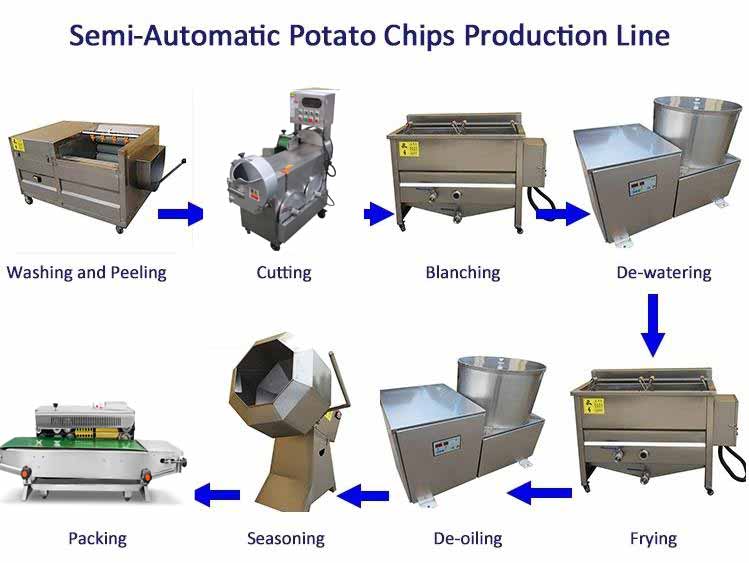

Production flow chart

Purpose of each machine

1. Elevator feeder: To conveyor the fresh potatoes to the washing&peeling machine.

2.Washing&peeling machine: To remove potato skin and soil.

3. Picking line: Workers select the unpeeled potatoes and trim them for better quality.

4. Slicing machine: Cut the potato into a slice

5. Rinsing machine: To wash off the starch of the potato chips

6. Blanching machine: To keep the fresh color and original flavor

7. Vibrating machine: Remove the extra water by high-frequency vibration after blanching.

8. De-water machine: To remove the water from the surface.

9. Continuous frying machine: To fry the fresh potato chips

10. De-oil machine: Remove the excess oil from the chip’s surface.

11. Vibrating machine: Remove the extra oil by high-frequency vibration.

12. Seasoning machine: Mix the seasonings and potato chips evenly

13. Automatic packing machine: Automatic weighing, packing, and sealing.

Main parameters of 100kg/h production line(Electric heating)

Workshop >100m2

Consumption of electric:160kw*h

Quantity of workers:5-6 persons

|

No. |

Name |

Dimension |

Power |

|

1 |

Elevator feeding |

2.6*0.8*1.7m |

0.55kw |

|

2 |

Washing&peeling machine |

3.2*0.8*1.5m |

2.2kw |

|

3 |

Picking line |

3*0.8*1.1m |

1.5kw |

|

4 |

Slicing machine |

0.76*0.56*0.93m |

0.75kw |

|

5 |

Air bubble washing machine |

3.5*1.25*1.05m |

1.87kw |

|

6 |

Blanching machine |

4.5*1.58*1.1m |

60kw |

|

7 |

Vibrating de-watering machine |

2*0.9*1m |

0.8kw |

|

8 |

Air blowing de-water machine |

4*0.8*1.5m |

3.7kw |

|

9 |

Continuous frying machine |

5.5*1.5*2m |

120kw |

|

10 |

Vibrating de-oil machine |

2*0.9*1m |

0.8kw |

|

11 |

Air blowing de-oil machine |

6*1*.12m |

3.7kw |

|

12 |

Seasoning machine |

3.2*0.7*1.6m |

1.1kw |

|

13 |

Automatic packing machine |

1.35*1.2*1.5m |

6kw |